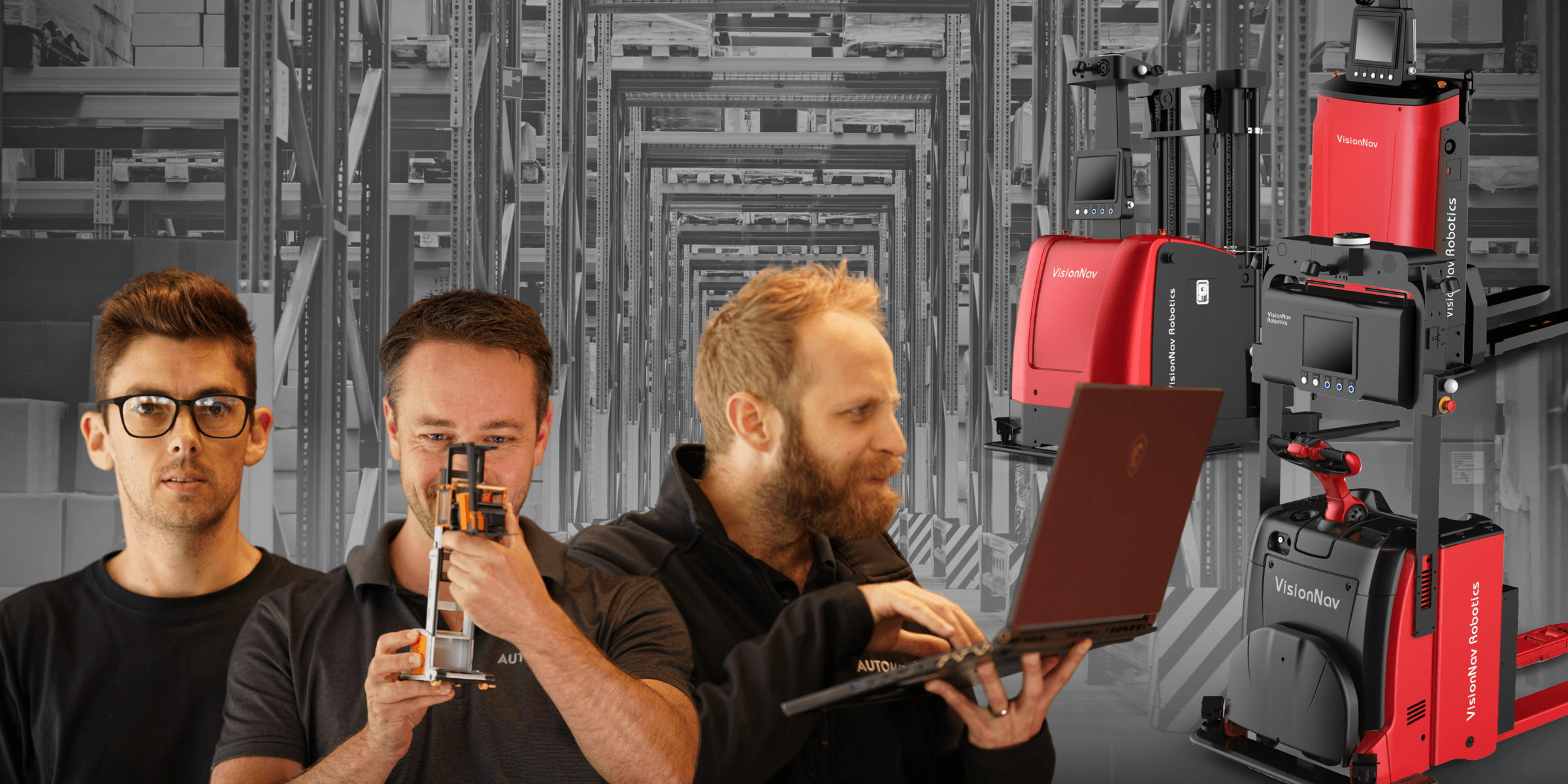

Automate-X are bringing VisionNav to the New Zealand market

Automated Guided Vehicle - AGVs

The future of autonomous logistics and pallet movements

Automated Guided Vehicles

Internal transportation and material handling play a fundamental part in logistics success. The autonomous mobile robots (AMRs) from MiR can smoothly optimize these workflows.

Intralogistics Automated Guided Vehicles & Forklifts

A new generation of automated guided vehicles are changing the way businesses and manufacturing plants move materials and pallets. Get rolling with a new generation of powerful, smart and user friendly AGVs that is driving logistics and materials movement, both easily and cost effectively.

Autonomous Pallet Stacker

Automatic and flexible material handling, material inbound and outbound to improve your logistics efficiency. An Automated Guided Vehicle can work with varied carriers such as pallets, storage cages, and able to dock with WMS. It is also equipped with 360° anti-collision protection and auto charging function to enable it to work in complex situations.

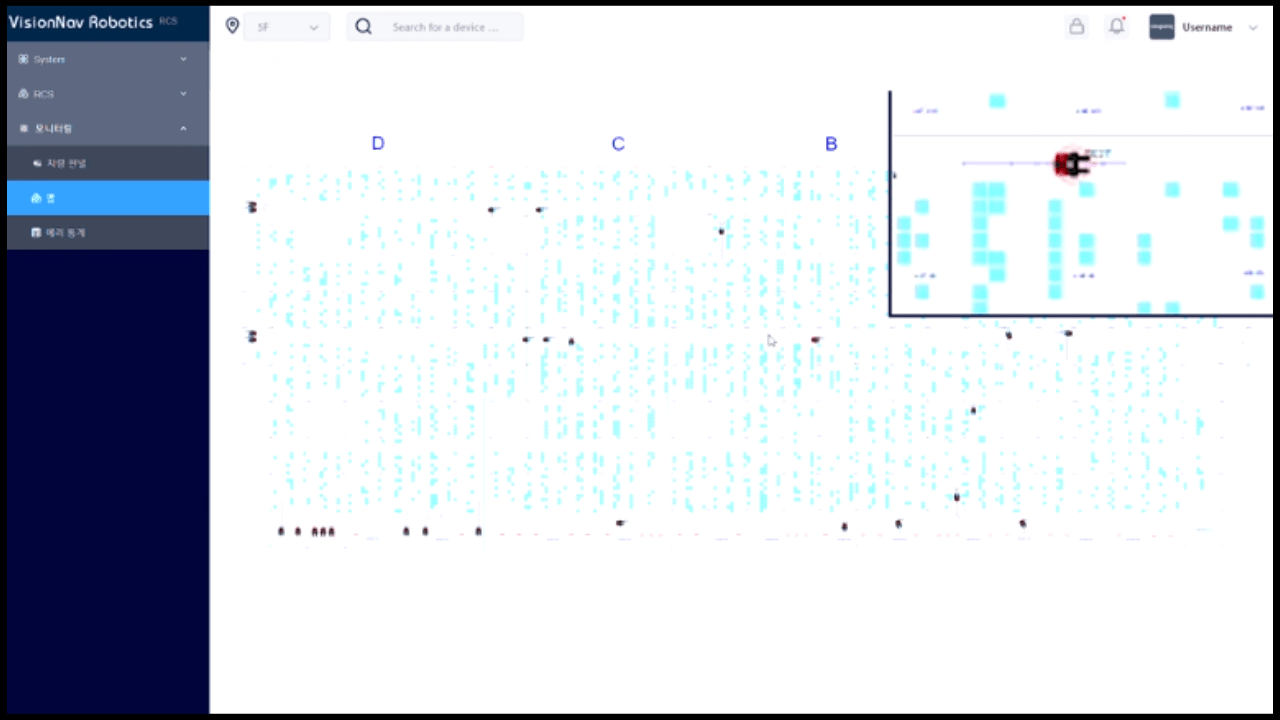

AGV Navigation Control System

The robot control system (RCS) can provide functions such as Automated Guided Vehicle management, real-time operation map, instruction management, task management, abnormal information management, etc. and It can also support a series of information management tasks before, during and after the operation of AGVs.

Dedicated mobile robotics team

We have a dedicated team in New Zealand which focuses on Mobile Industrial Robotics. Our Automate-X mobile robotics division is working on a variety of autonomous and mobile robotic technologies. All the way from AGVs & AMRs through to Goods-to-person case handling robots. We have you covered as the experts in the latest mobile technologies.

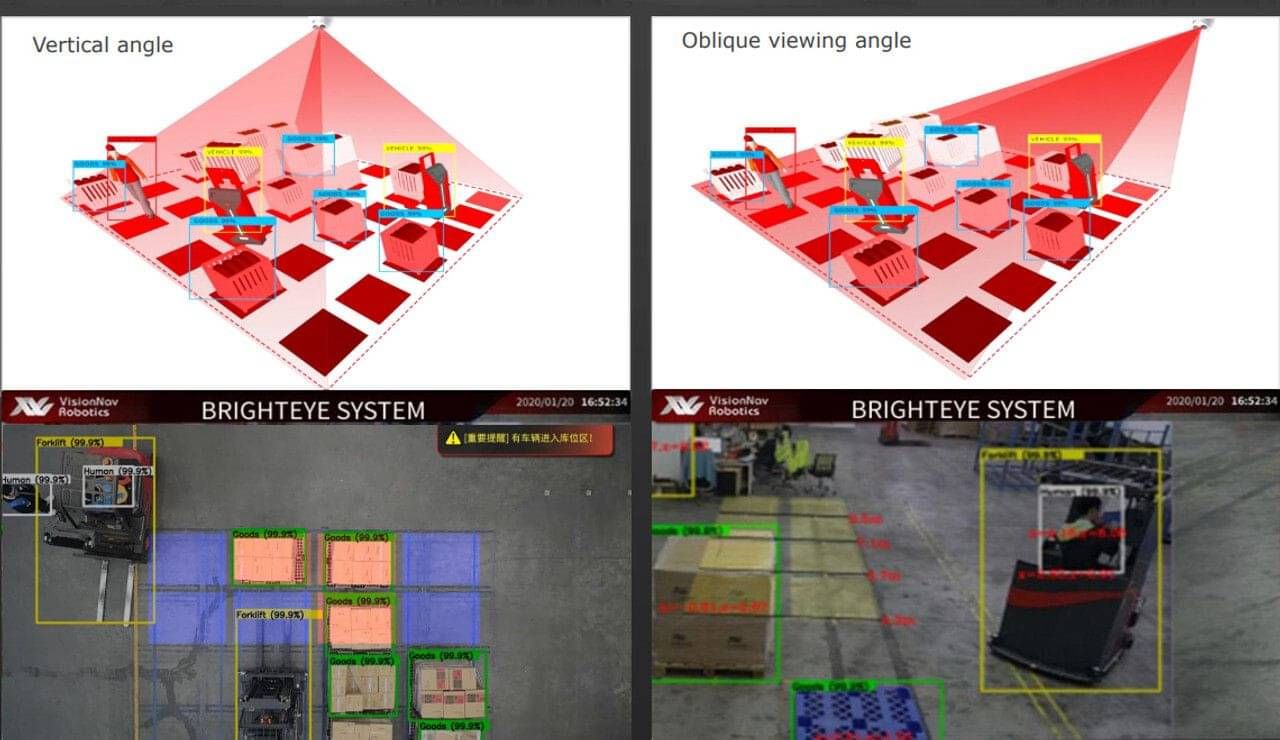

AGV Brighteye Vision System

Bright Eyes Vision System - Through real-time, the system monitors storage positions & staging area on the floor. Bright Eye system also has the ability for buffering goods and persons in a specific zone. Bright Eye can make the early warnings of an AGVs pathway and notify of collision for carried loads.

Put away and picking

AGV will arrive at a designated storage location, such as a rack or a shelving system, where it will use a lift mechanism to raise the pallet to the appropriate level for storage. The AGV will then use its navigation system to precisely position the pallet in the designated storage location.

Outdoors Tow Tractor

Designed for transporting materials and equipment over long distances. These AGVs can operate outdoors, day and night, making them highly versatile. These AGVs use sensors and mapping technology to navigate within a facility while adhering to a predetermined course.

Truck loading & unloading

The AGV navigates to a designated location, such as a loading dock, where a truck is parked. For loading, the AGV will place the materials onto the truck, while for unloading, the AGV will retrieve the materials from the truck. The AGV can then autonomously place the pallets on the floor in a specific pattern

Floor staging or movements

Floor staging is a method of using AGVs to stage materials, such as boxes or pallets, on the floor within a warehouse or manufacturing facility. An AGV can also be programmed to arrange the materials in a specific pattern or order. This process allows for the efficient, accurate and safe movement of materials within a facility

‘We’d recommend Automate-X to others...’

"We’ve found Automate-X easy to deal with and focused on industrial automation solutions. They’ve been readily available for questions and ongoing service. Not being tied to one supplier or brand means that they can provide equipment and solutions for all the different systems we have on site.

The project and ongoing service have been enjoyable and we’d recommend Automate-X to others."

- Sam Corbett, Senior Terminal Engineer

AGVs for Warehouses

The need for consistent and measurable automated intralogistics and materials handling are at an all-time high, putting additional strain on your employees and organization.

It’s time to change the way you think about warehouse automation and logistics with AGVs, the fully automated guided vehicles. Built from the ground up by the team at VisionNav®, our AGVs deliver a consistent, efficient and measurable internal logistics so your operation can work around the clock without stopping.

Ready to meet VisionNav?

Whether you’re ready to experience the future of autonomous forklifts, or you’d simply like to learn why our Autonomous Guided Vehicles makes smarter business sense, we're ready to speak with you.