Autonomous Mobile Robot AMR

A new generation of AMR autonomous mobile industrial robots is changing the way business move materials. Get rolling with a new generation of powerful, smart and user friendly autonomous mobile robots that is driving logistics and materials movement, both easily and cost effectively.

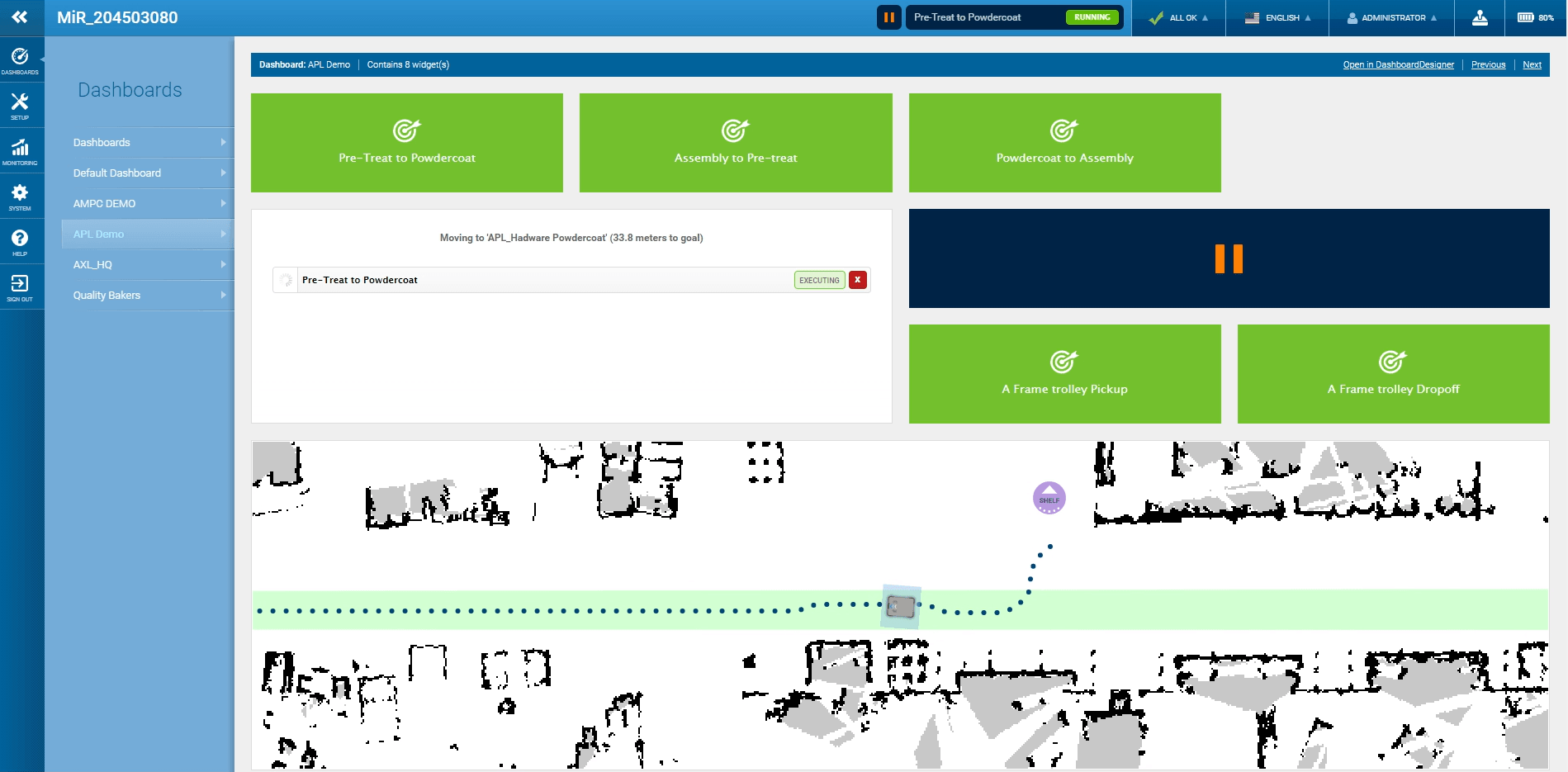

MiR Robots

Internal transportation and material handling play a fundamental part in logistics success. The autonomous mobile robots (AMRs) from MiR can smoothly optimize these workflows.

Get in touch with us for a 3D simulation

Easy Programming

By simply downloading CAD files of the building directly to the robot, or programming with an intuitive web-based interface, Automate-X can get rolling quickly and deploy missions within hours.

The industrial mobile robotics mission can be easily operated, adapted or assessed using common networked smartphone, tablet or computers.

Smart & Safe

With powerful SICK Lidar scanning sensor technology, there is no need to alter your facility. Built in sensors and cameras are connected to sophisticated software, that enables the MiR robots to identify its surroundings and not only take the most efficient route to its destination, but to ensure all obstacles and people are safely avoided.

Advanced dual-laser scanner

LiDAR scanners for live obstacle detection

3D cameras for increased safety

Detects obstacles up to 1700mm in height

8 proximity sensors

Sensors for low lying object detection

Many accessories and top modules

Easily customize your MiR robot with off the shelf solutions

Faster supply chain

Removing human decision making from the supply chain decreases the rate of errors, required quality checks and collisions. All of these contribute to a slowed or halted process. By adding sophisticated AMR technology to the mix, manufacturers can see an improved offering from day 1.

Limited downtime

While there is complex technology and data behind MiR AMRs, their set up and use is anything but. Unlike AGVs, which require refitting of the shop floor, MiR AMRs can be implemented quickly, ensuring that there is no downtime in other processes when the robots are deployed.

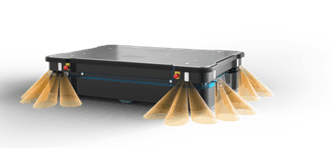

MiR 250 on-site Demo

Automate-X is able to provide an on-site demonstration of the MiR250 with top shelf. We have a custom built trolley to test out your application. We are able to set-up a demo in a number of hours.