Optimising Automation budget

Share on

How to avoid wasting Automation budget

Imagine this- Your business has decided to automate because it can deliver huge process savings, but your list of automation projects is long, there are multiple ideas coming in from your organisation, and there is no clear place on where to start.

In order to provide evidence to support industrial automation choices, you must assess and rank the processes according to the value of the benefits and their ROI.

So where do you start?

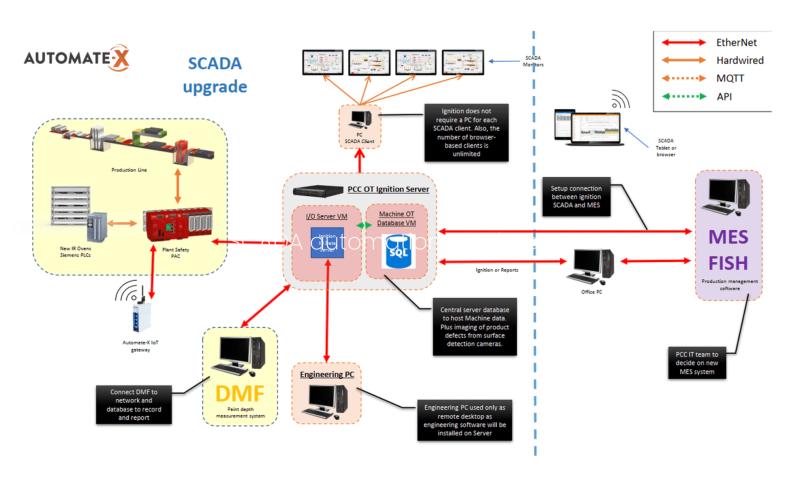

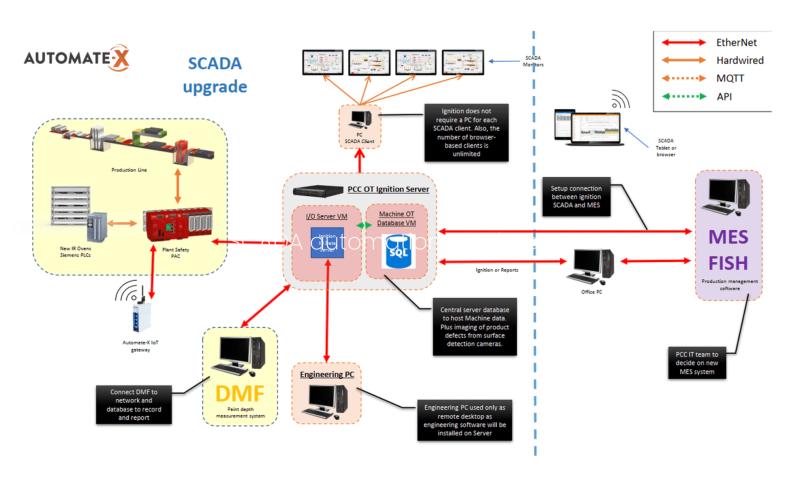

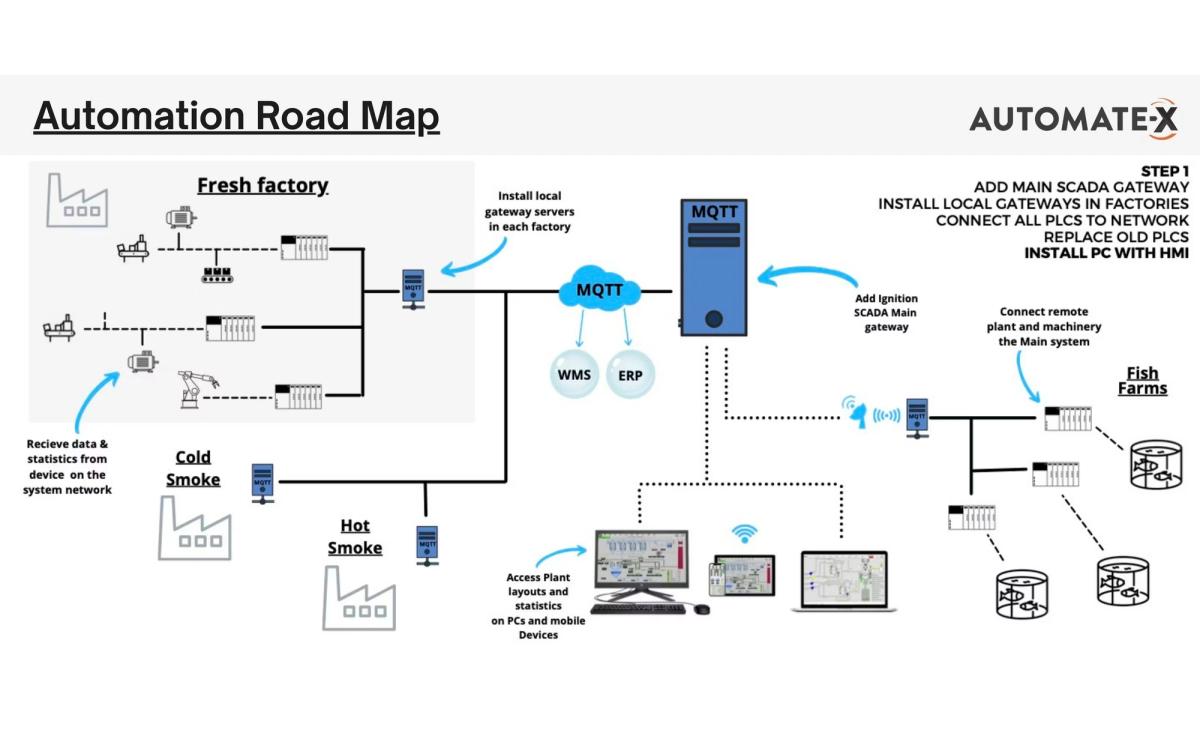

Manufacturing or industrial automation roadmap. This small upfront investment will help plan the way to the end goal and make your organisation have those conversations on "where do we want to be 5 or 10 years from now"

Smart Automation Industry 4.0

You ought to concentrate your automation efforts and resources on the possibilities with the greatest likelihood of success and influence, the so-called, low-hanging fruit. Essentially, saving you money on failed projects or equipment that may need replacing in a short time span.

A unified process and approach are required so that your firm can assess and rank automation prospects. By using this strategy, you'll be able to swiftly create and apply a defined set of criteria to identify which operations are strong candidates for automation. To gauge their prospective advantages, you can examine those options. After that, you may decide which procedures to tackle first and prioritise them.

By evaluating complexity versus value at a more precise level and giving the information required to support your prioritisation, you can now go from broad qualification criteria to specific priority factors.

Do you have a roadmap and follow?