Tip Top

ClientTip Top

IndustryManufacturing

SystemMachine Vision, Conveyor Solution

PublishedJuly 13, 2023

OUR VALUES

Tip Top Ice Cream wanted to enhance its production process by improving the accuracy and efficiency of its quality assurance system. With multiple production lines and variations in product orientation, ensuring that each tub’s label and contents matched correctly was a significant challenge. Without automation, there was a risk of mismatched products, such as vanilla ice cream being packaged under a chocolate label, impacting brand trust and product consistency.

OUR VALUES

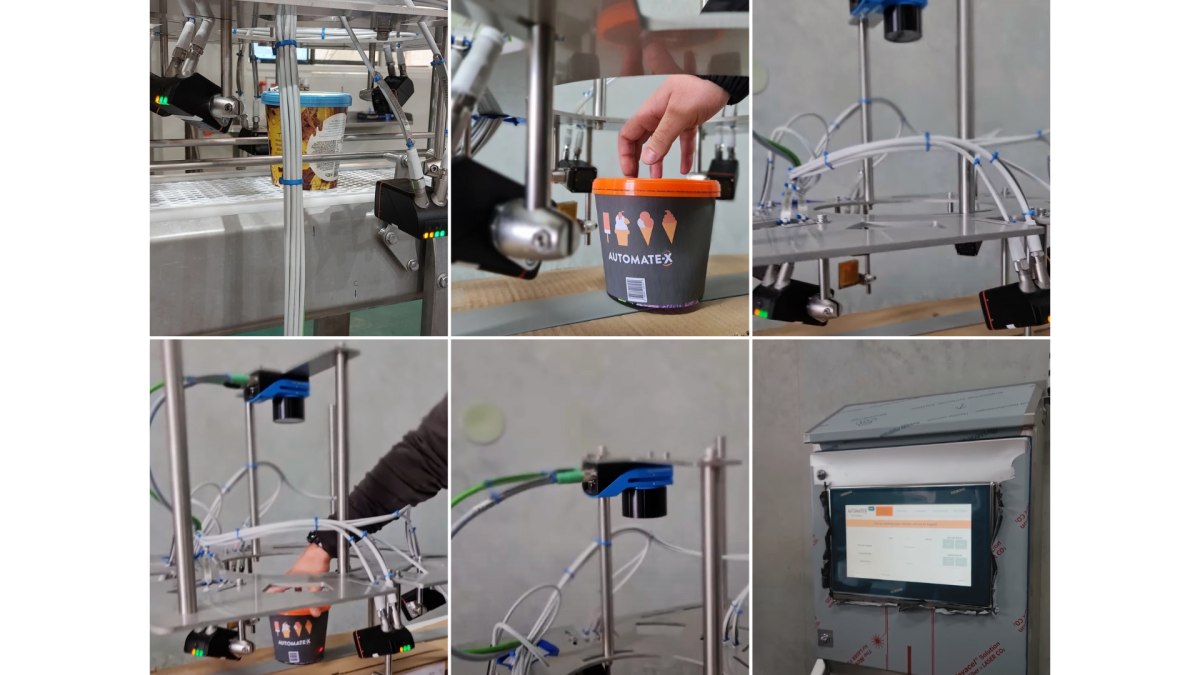

Automate-X collaborated with Tip Top to design and implement a Quality Assurance Inspection System that automates label detection across three production lines—A, B, and C. Each line was equipped to verify that the barcode on the tub matched the recipe selection, ensuring the right product in every package. For production lines B and C, a single barcode scanner was configured to handle multiple tub orientations, allowing for flexible and precise scanning. The system was designed to detect mismatches instantly, maintaining quality and consistency at scale.

OUR VALUES

To achieve accurate inspection and reliable performance, Automate-X deployed an array of six barcode scanners positioned along the conveyor to capture every angle of the tubs. Above the line, a smart camera was installed to identify and verify the lid artwork. Both the scanners and camera were housed within a light-controlled compartment to prevent interference from ambient lighting, ensuring precise detection and robust quality control in real-time.