Peace of mind with our Machine Safety

Your people are your business’s greatest asset. Therefore, ensuring their safety while operating and maintaining plant and machinery is imperative. Our Certified Machine Safety Experts (CMSE®) bring experience and a systematic process to help ensure your equipment is safe and compliant.

Automate-X's safety engineers progress the safety process from the beginning all the way through to on-site commissioning and verification. In conjunction with local machine safety standards like AS4024, or international ISO and IEC standards. Automate-X provide you will all the documentation to leave your business and employees protected from accidents and litigation.

Designers, manufacturers, suppliers and employers all have responsibilities to ensure machinery is safe to use - WorkSafe NZ

Machine safety process

We take a structured approach to our safety engineering. This provides a process that conforms to safety standards like AS4024 and helps ensure a solution is designed and implemented in a compliant way. We have refined our process to make your machinery safe - without breaking the bank.

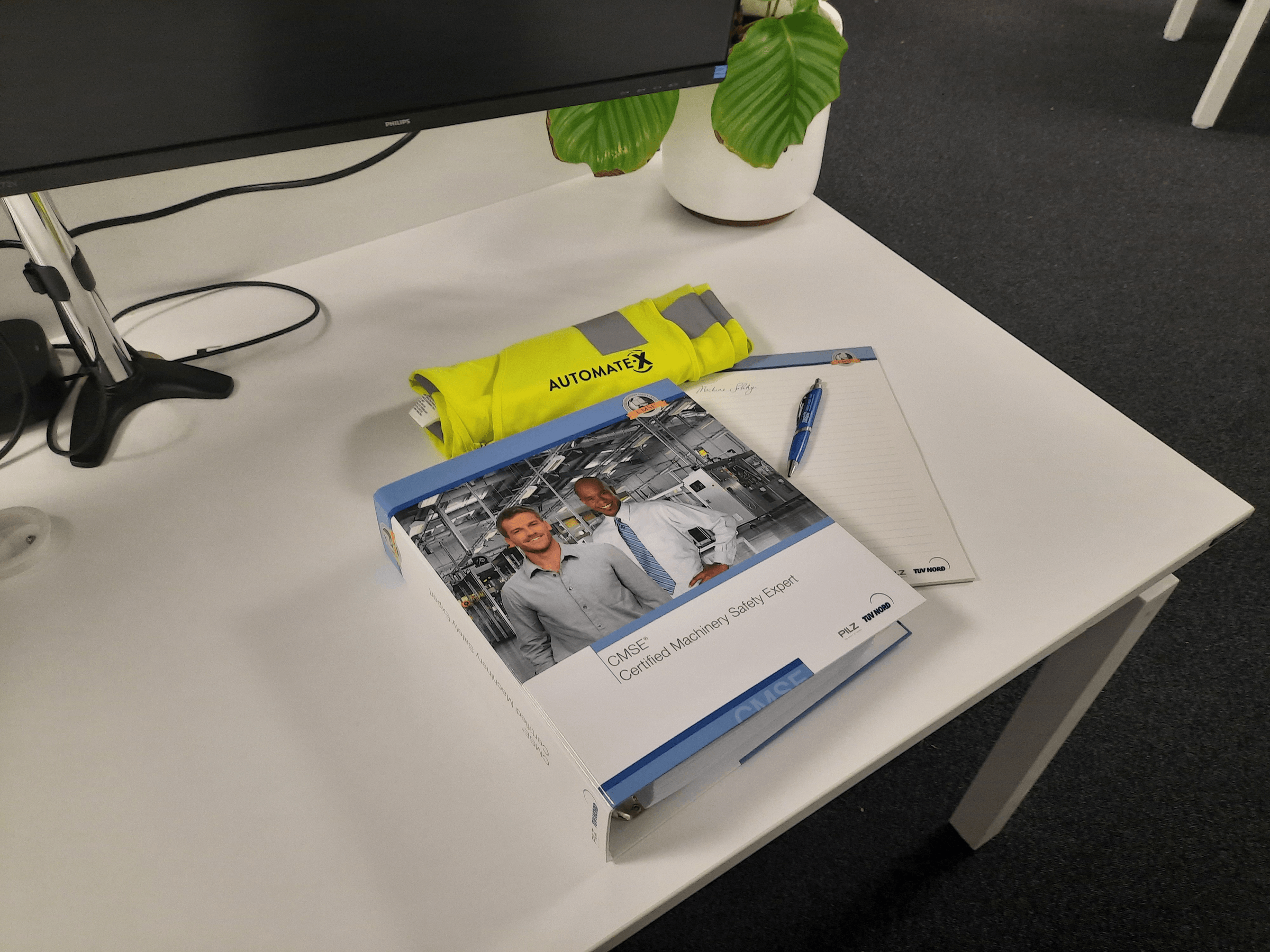

CMSE®

Our Certified Machinery Safety Experts have the training and experience to engineer solutions to complex machine safety challenges.

The certification shows our engineers understand the requirements outlined in regulations and standards. We apply this understanding through the design process to deliver a safety solution that provides a safe work environment for your team.

Compliance and certification

The process and documentation ensure that your system is compliant and certified based on the required standards. We provide you with complete documentation set upon final validation of the machinery.

Our CMSE® engineers are experienced and trained to design by international & local standards like AS/NZS4024 - Safety of machinery, and AS/NZS3000 - Electrical Installations

Safety guarding/fencing

Fencing and guarding are generally the most cost-effective method to reduce the personal risks on machinery. Along with the design of safety fencing, Automate-X can design and implement guards to minimise or eliminate any hazards.

Machine Safety

Your people are your business’s greatest asset. Therefore, ensuring their safety while operating and maintaining plant and machinery is imperative. Our Certified Machine Safety Experts (CMSE®) bring experience and a systematic process to help ensure your equipment is safe and compliant.